How To Extract Gold From Electronics

Looks legit.

Published 11 years ago

Looks legit.

1

There are basically two methods of melting gold flakes and dust to recover gold available to the average person, the mercury method called Gold-Mercury Amalgam with its obviously toxic by-products and the Borax Method. The Borax Method is a technique of artisanal gold mining, with its basis in the principle that borax reduces the melting point of all minerals, including precious metals like gold. The melting point of gold is 1063 730C, which is a higher temperature than can be obtained by cheap torches and burners. By adding borax to the heavy mineral concentrate, the melting point temperature decreases, allowing people to melt gold out of their concentrate and salvage. By using borax, no mercury flour is produced, and gold recovery increases.4

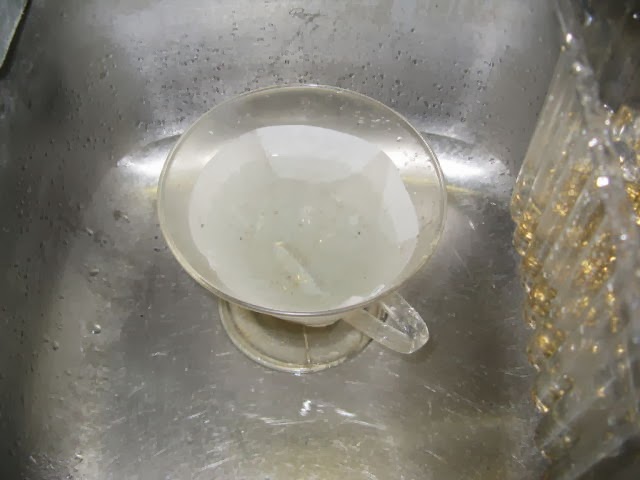

After you have sorted the circuit board parts pour the water off through the coffee filter and flush with methyl hydrate to clean. Since the methyl hydrate is 99.9 methyl alcohol it cleans and dries the gold flakes better and faster than water, water will cling to the gold flakes and give you a false weight.36

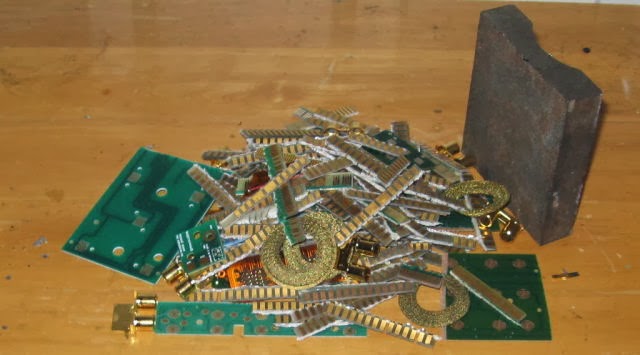

Put the gold fingers and clean circuit boards in the coffee pot, in another container mix two parts muriatic acid and one part hydrogen peroxide and add to the coffee pot until it just covers the gold fingers and wait a week giving it a stir daily. Since I have a week I will move on to processing my solid low grade gold parts.38

My RCBS scale is accurate to 110th of a grain when setup right however do not go by the Oz to grain chart on the scale. A grain is a grain however a troy Oz is 112th of a troy pound and a regular Oz is 116th of a pound so a Troy Oz is 480 grains not 437.5 grains. Setup the scale remembering to zero it by adjusting the screw on the left.41

Cupellation is a process where ores or alloyed metals are treated under high temperatures and controlled operations to separate noble metals, like gold and silver, from base metals like led, copper, zinc, and others present in the ore or alloyed metal. The process is based on the principle that precious metals do not oxidize or react chemically, like the base metals so when they are heated at high temperatures, the precious metals remain apart and the others react forming slags or other compounds. This process has been in use since the Bronze Age and still used today able to raise the gold and silver content to 95, however the process cannot separate silver from gold, but this is good enough for me.